Diy Slot Mortiser

The STS Slot Mortiser solves this by providing positioning scales for both the mortise length stop blocks, and for the distance of the integrated fence from that bit. Setting the width and depth of cut takes only a few seconds, and you can return to a position for repeat cuts reliably and just as fast. Three Axis Slot Mortiser Plan Posted on: July, 18, 2016, in How would you like to be able to cut a mortise in less time than it took to read this sentence? Almost all of my students, and everyone who uses, or sees our shop made slot mortiser in action, just has to have one! Now you can build your own, using common shop materials and supplies!

Messages Archive 2007

Paul Cates - Henderson, KY

>Hi everyone,

This is my first attempt at posting pictures…hope it works!

Diy Slot Mortiser

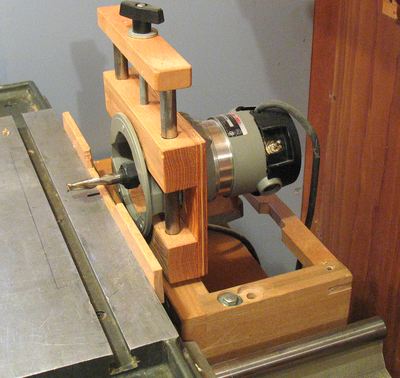

When I owned a Rojek mortiser, it was my favorite power tool, so after I sold it I decided to try to build something similar but cheaper. For the up/down adjustment, I found the following hunk of iron at a local surplus dealer for $100. It was greasy and a bit rusty, so I spent some time cleaning, sanding and repainting.

I used the 40 (mm) series 8020 linear bearings because at the time of purchase, 8020’s surplus site on eBay had both the rails and bearings in stock. The 40 series is plenty beefy, so I think the smaller sizes would work fine. The head of a 5/16” carriage bolt fits nicely into the rail slots to secure the rails to the cast table. 8020 also sells shims to make the bearings fit snugly to the rails. These are not mandatory if the bolt holes in the table are large enough to allow you to adjust the bearings to ride against the rails, but the shims are an easy way to remove slop while moving the X-Y table (vs. endless adjustments without them). DAMHIKT!

I investigated using an induction motor with a chuck attached to either the motor shaft or a mandrel, but it seemed more trouble/expense that it was worth, thus I went the router route. I made the box holding the Bosch 1617 EVS router out of plywood, with a detachable top/back. I bought the variable speed router thinking I could use it at less than full speed to cut down on the noise. It works fine, but if I had to do it over, I’d probably use a more powerful router. I can imagine a piece of red oak stopping the Bosch with a ½” bit on low speed. Rick L. gave me lots of pointers and advice via email, and I copied some of the features of Dan Barber’s Mortise-Flex (see the articles section here on WC).

The port for dust collection is on the back:

Side to side adjustments and hold downs:

To make the lever, I bought some rod ends on eBay but couldn’t find a solid steel rod to fit through the rod end without a lot of slop. ½” was too big, so I used a 3/8” threaded rod on the inside of a hollow aluminum tube. There is a little flex in the lever, but it works fine.

I posted a video of the mortiser in action at the link below. It’s an 11mb file. The speed is set on 4 (out of 6) and I’m cutting a mortise in cherry with a two flute 3/8” end mill.

Messages In This Thread

- Homemade slot mortiser w/ PICS *LINK* -- Paul Cates - Henderson, KY -- 3/8/2007, 6:59 pm

- Re: Costs of 80/20 -- Rick L -- 3/12/2007, 11:06 am

- Re: Costs of 80/20 -- Paul Cates - Henderson, KY -- 3/12/2007, 3:06 pm

- Re:Shaft material -- Rick L -- 3/12/2007, 3:25 pm

- Thanks *NM* -- Paul Cates - Henderson, KY -- 3/12/2007, 7:40 pm

- Re:Shaft material -- Rick L -- 3/12/2007, 3:25 pm

- Re: Costs of 80/20 -- Paul Cates - Henderson, KY -- 3/12/2007, 3:06 pm

- Re: Homemade slot mortiser w/ PICS -- Paul Cates - Henderson, KY -- 3/11/2007, 10:32 pm

- Re: Thoughts... -- Rick L -- 3/10/2007, 10:13 pm

- Well done Paul -- HC Sakman -- 3/10/2007, 11:34 am

- Re: Well done Paul -- Paul Cates - Henderson, KY -- 3/10/2007, 6:17 pm

- BRAVO! -- Dan Barber -- 3/9/2007, 8:36 pm

- Nice job, Paul. Great dust collection. -- Eddie Pacheco, San Jose, Ca. -- 3/9/2007, 10:53 am

- Re: Homemade slot mortiser w/ PICS -- Jesse in New Mexico -- 3/9/2007, 10:27 am

- Re: Homemade slot mortiser w/ PICS -- Paul Cates - Henderson, KY -- 3/9/2007, 5:11 pm

- Nice setup Paul -- Jim Dillon -- 3/9/2007, 7:40 am

- Awesome! *NM* -- Mark Goodall - ATL - tooljunkie -- 3/9/2007, 7:03 am

- Re: Homemade slot mortiser w/ PICS -- Robert R Clough - Thorncraft -- 3/8/2007, 8:57 pm

- Paul -- Very Cool Tool! *NM* -- Paul Kramer -- 3/8/2007, 8:01 pm

- Re: Costs of 80/20 -- Rick L -- 3/12/2007, 11:06 am

Messages Archive 2007 is maintained by Ellis Walentine

Powered by Tetra-WebBBS 6.21 / TetraBB PRO 0.22 © 2006-2012 tetrabb.com

1 wallclock secs ( 0.22 usr + 0.03 sys = 0.25 CPU)

Introduction: Horizontal Slot Mortiser

Tech in wood joinery meets handcrafted design + build. The top part is a mortising unit, below is a micro-adjust created using traditional methods. The story follows. I purchased this Jessem Mortise Mill unit a few years back and although I managed to produce some loose tenon slots successfully, it was not easy to set up. I can’t recall the issues exactly, but it was frustrating at times. So recently found the unit buried under a secondary workbench and decided I would make an effort at getting it to work successfully.

I had always wanted a horizontal slot mortiser setup and thought why not set this up to create slots in the horizontal plane instead of the vertical plane. The unit was marketed to be installed vertically with board placement underneath. Notice the etchings on the Mortise Mill are upside down. I’m not sure if having boards hanging below the unit contributed to the issues I had at the time, but nonetheless I wanted to mount it so loose tenon slots were created horizontally. Today, I use this slot mortise extensively in my furniture studio at Pirollo Design. Woodworking courses, woodworking plans and classes also available through WoodSkills

Step 1: A Suitable Platform

These images show the unit assembled to a rolling cart before building the micro-adjust unit. It was critical to find a suitable platform, i.e. workbench surface to be able to mount it. A rolling cart in my workshop was ideal since I could wheel the unit away when not in use and the footprint of the Mortise Mill was not large. The rolling cart has large locking casters which do a good job of keeping the cart immobile. I installed it so the surface of the base plate was even with the surface of the cart, this took some time. Large enough 1/4-20 bolts were used to maintain rigidity and keep it from shifting.

Tested it afterwards and I was pleased with the results. The later addition of a L-shaped wood bracket to support stiles while they were being mortised worked well. The ends of rails to be mortised were easily supported by the wood surface of the rolling cart. Further testing with clamping of boards provided me with a repeatable setup. I liked the fact that I could permanently leave the Mortise Mill bolted to the rolling cart and continue to use the complete top surface of the rolling cart as before.

Step 2: Micro-Adjust

An issue that soon came up was the vertical adjustment of the mortise slots on a horizontally-oriented board. Since the Mortise Mill was installed horizontally with horizontal board placement instead of vertical, the slot location adjustment was not as smooth as I would like due to the weight of the sliding component of the unit. I decided to build a micro-adjust setup to alleviate the problem. This was performed using some scrap walnut and maple. As can be seen in the pic, it is all wood construction with a 1/2 inch lead screw and wood handle. The end of the lead screw has a custom cradle contoured to fit the bottom edge of the sliding part of the Mortise Mill. Now I could precisely dial-in slot placements!

Diy Slot Mortiser Bit

Step 3: Horizontal Slot Mortiser

Since the micro-adjust is cantilevered off the vertical posts of the rolling cart, I beefed up the supports. It is probably over-engineered now. Things to watch are the exact placement of the tip of the lead screw over the center of the edge of the Mortise Mill for smooth operation. A large paddle switch for the built-in Mortise Mill dust collection was installed for convenient access. The end result is a functional horizontal slot mortiser that provides precise adjustment of the slots. The rolling cart top serves as an excellent support for boards as can be seen in the images. The other images demonstrate how accurate the slots are for loosed tenon installation.

I don't have a plan for this at this time as you would need to acquire the Jessem Mortise Mill for this particular setup. Other plans, woodworking courses and classes are available at: WoodSkills

1 Person Made This Project!

- woodskills made it!

Recommendations

Horizontal Slot Mortiser

Griggio Slot Mortiser

Plywood Challenge

Plastic Contest

Battery Powered Contest